Folding hatch covers

With today’s drive for ever more efficient cargo handling practices in port, modern dry cargo vessels tend to have larger hatch openings relative to the size of vessel’s deck area. This means that there is less stowage space available for hatch covers, which has made our compact folding hatch covers increasingly popular.

Folding hatch covers for general cargo / multi-purpose vessels

It is important for all cargo ships that weather deck and cargo space layouts are designed with the highest possible level of cargo handling efficiency in mind. This allows for fast and safe loading. MacGregor makes sure that the arrangement of hatch covers, sealings, support pads and locators on board your ship are optimised to deliver uncompromised weathertightness to protect the cargo and to ensure safety.

The efficient use of cargo space is of utmost importance for general cargo vessels. Folding hatch covers are designed to carry various deck cargoes and to form functional cargo areas to facilitate flexible cargo operations. In an open position they provide access to the hold for loading and discharging cargo and in the closed position they seal the hatchway in a weathertight manner. Tweendeck folding hatch covers are also available.

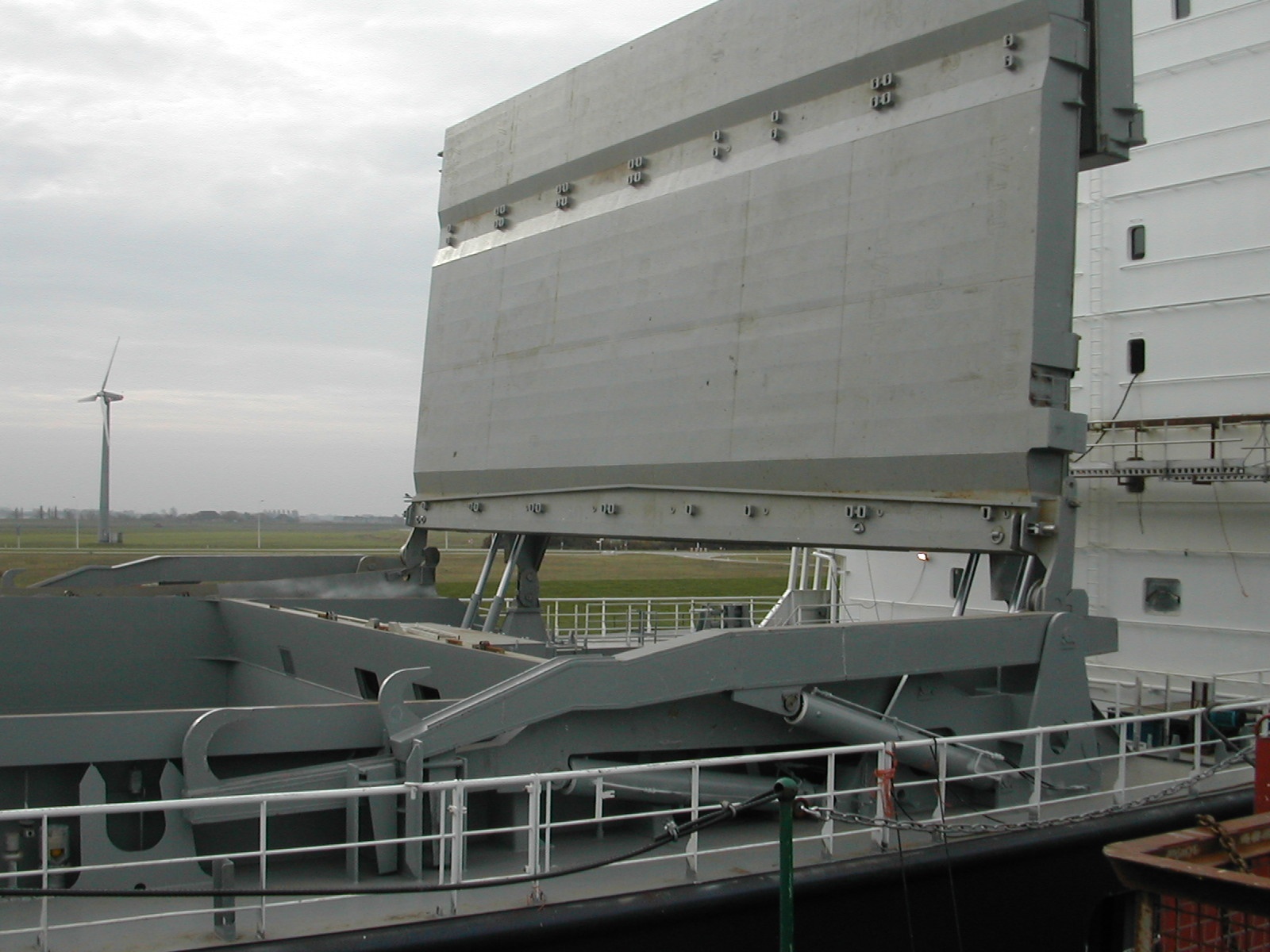

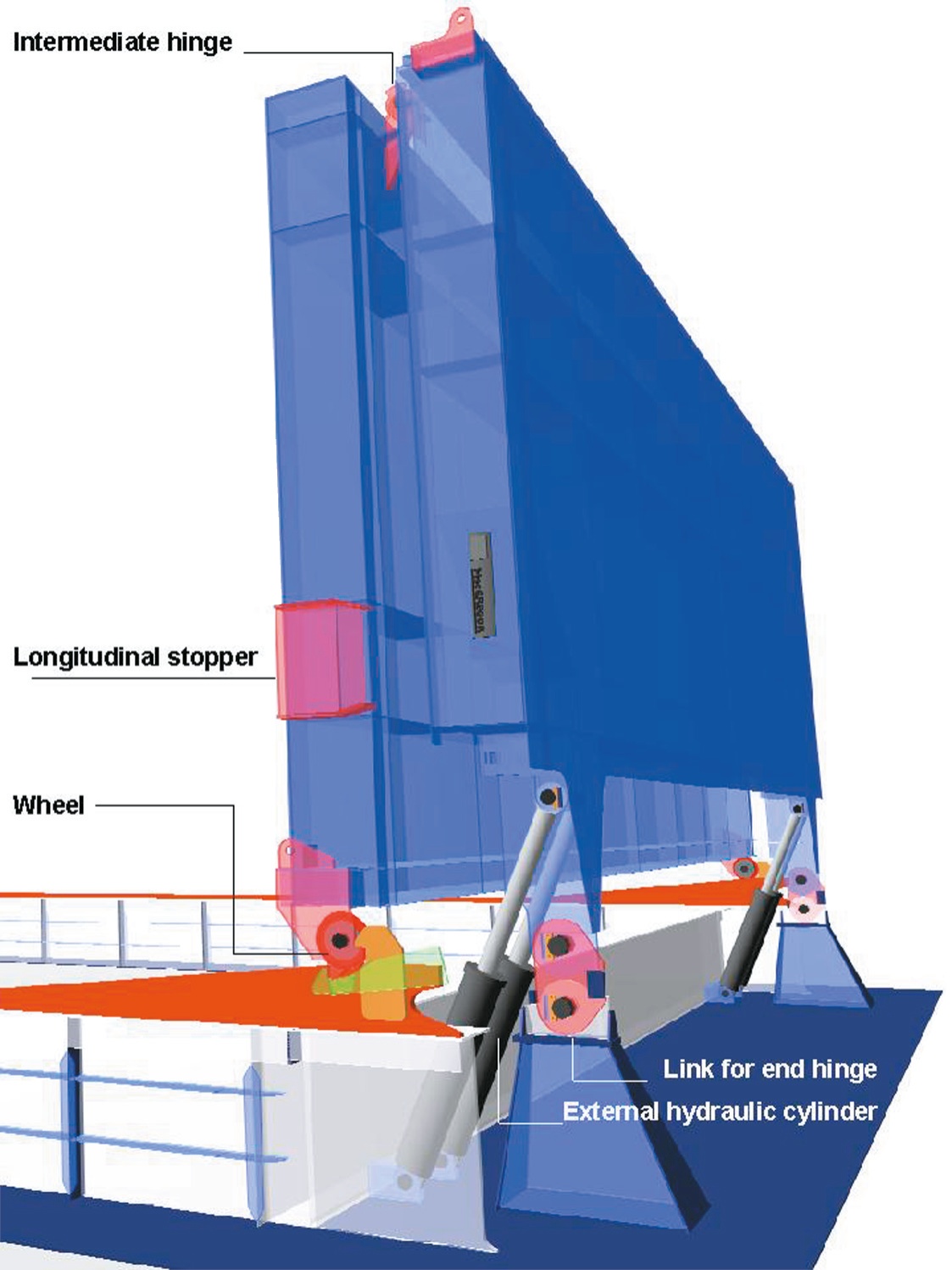

MacGregor hydraulic folding covers consist of two (or more) panels, which are connected by hinges to form a folding pair. In many cases, the hatch cover comprises two folding pairs. One pair is stowed at the aft end of the hatch and the other forward.

The folding pair is operated by hydraulic cylinders acting directly on the end hinge arms, which are connected at stools on the deck. When the cylinders push the end panel up from the closed position, the cover folds and the second panel, fitted with wheels, rolls on rails to a stowage position. The panels are usually secured in the open position by semi-automatic locking devices interacting with the wheel arms.

Sizes to suit all

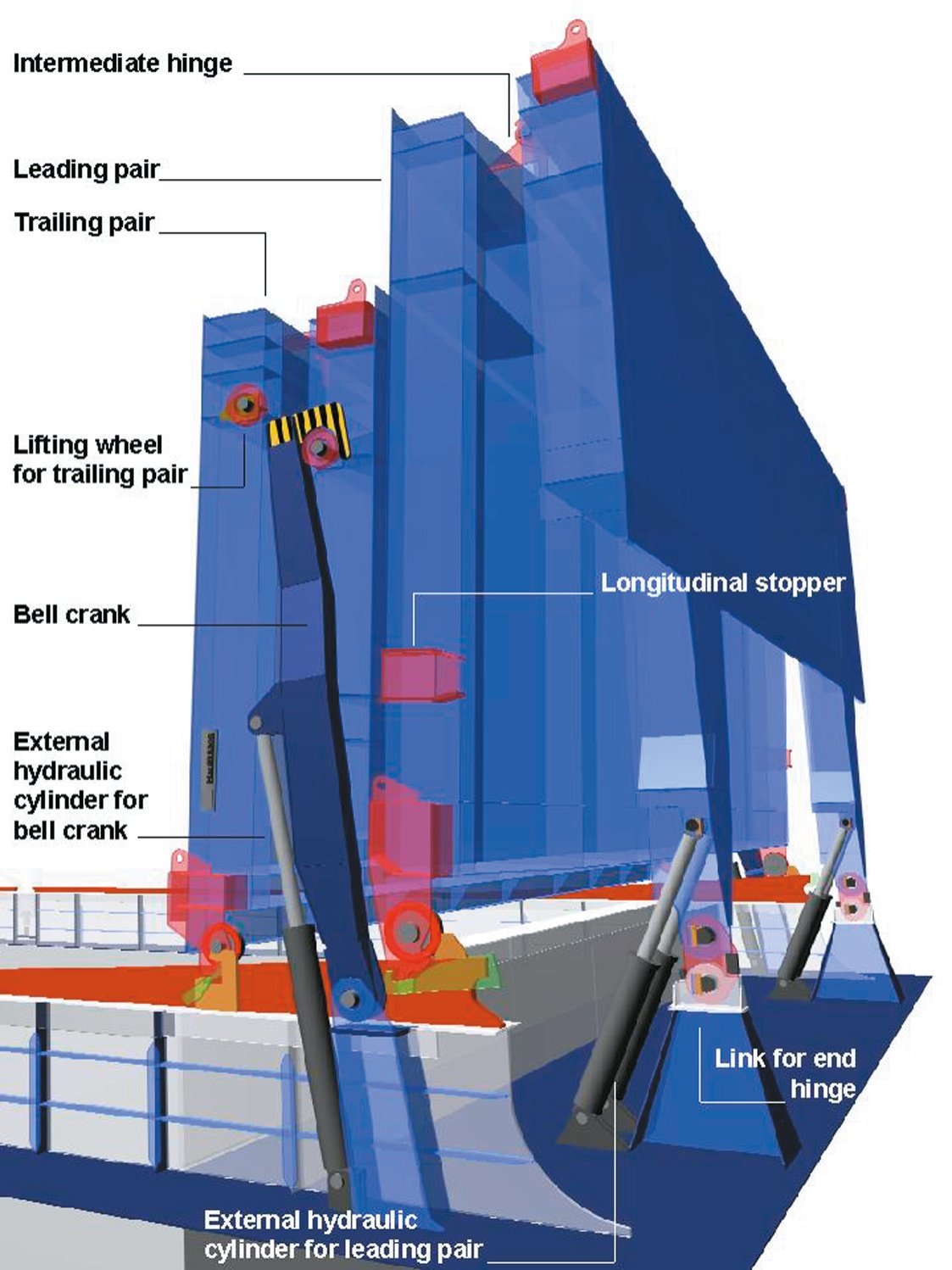

If the size of the planned cargo on board your ship calls for longer hatches, we can design a selection of multi-folding panels suited to meet these needs. The number of folding panels forming a functioning unit can be two, three, four or six. By combining two units (stowing forward and aft) the total number of folding panels can be up to 12. The panels are connected by hinges to form pairs of panels. The pair connected to the end hinges is called the leading pair. Additional pairs of panels are called trailing pairs. They are connected by intermediate hinges to the leading pair to form one unit.

The leading pair is most often operated as the folding cover, that is, by hydraulic cylinders acting directly on the end hinge arms. The trailing pairs are often operated by hydraulic bell crank arms. These are long, strong arms, connected pivotally outside the longitudinal coamings. They interact with respective wheels on the first panel of the trailing pair, when being pushed up by hydraulic cylinders. In the six-panel units there are two sets of bell crank arms. With extremely wide hatches on a narrow ship, the first bell crank arms can be built into the hatchway under the leading pair.

The length of the hatch cover arrangement can also be increased by inserting rolling panels between the folding pairs. They can be towed by the folding cover and therefore open the desired section of the hatch for handling the cargo. They can also be designed for lifting ashore by container cranes.

Folding hatch covers for bulk carriers

Folding hatch covers are used on Handysize and Handymax bulk carriers, where it is particularly important to maximise hatch dimensions in relation to the ship’s beam. MacGregor’s reliable and proven folding hatch cover technology allows for efficient and safe cargo handling operations. This is especially important in remote ports, where maintenance services may not be available at short notice.

MacGregor hydraulic folding covers consist of two (or more) panels, which are connected by hinges to form a folding pair. In many cases, the hatch cover comprises two folding pairs. One pair is stowed at the aft end of the hatch and the other forward.

The folding pair is operated by hydraulic cylinders acting directly on the end hinge arms, which are connected at stools on the deck. When the cylinders push the end panel up from the closed position, the cover folds and the second panel, fitted with wheels, rolls on rails to a stowage position. The panels are usually secured in the open position by semi-automatic locking devices interacting with the wheel arms.

MacGregor recommends a double-skin panel design for folding hatch cover, which provides a smooth lower surface, making it easy to clean the inner skin that faces down towards the cargo hold. This speeds up the cleaning process between cargoes and enables shorter port turnarounds. A single-skin construction is prone to collecting cargo residue, which increases cleaning work.

The dimensions of other deck machinery, for example cranes, have to be carefully taken into account when designing the hatch cover arrangement and its stowage. MacGregor hatch covers, when designed in combination with MacGregor cranes, ensure a highly-efficient, well-functioning deck arrangement that optimises dry cargo flow.

Read more from our brochure: