Loose container fittings

MacGregor offers a wide range of MacGregor and Allset lashing products and cutting-edge lashing systems, which have designs based on decades of experience. Our lashings offer the highest possible cargo safety standards and are quick and easy to operate to meet tight port schedules and minimise downtime.

MacGregor loose lashings keeps your operation up and running throughout the lifetime of your ship

MacGregor has been a pioneering brand for container securing systems as a natural and essential part of its reliable and efficient cargo stowage solutions. It has always been clear to us that an integrated container stowage solution is more than a sum of its parts. Therefore, loose lashings for container securing form an important part of MacGregor product portfolio for container ships - together with hatch covers and lashing bridges.

MacGregor Fully Automatic Twistlocks (FAT)

Fully Automatic Twistlocks don’t require any manual operations on board, saving time in terminal operations and leading to faster turnaround times.

When the vessel is sailing, the automatic twistlock reliably secures containers together. At the port, it automatically engages containers during loading and opens automatically during discharging.

MacGregor Semi-automatic Twistlocks (SAT)

MacGregor’s wide range of semi-automatic twistlocks engage automatically once containers are placed on board, ensuring secure and reliable locking. Unlocking requires a simple manual pull of the twistlock release wires upon arrival at the terminal.

Designed to maximize safety for containers during transport, MacGregor’s semi-automatic twistlocks deliver exceptional reliability and unbeatable performance features. While manual release adds a small amount of time at the terminal, it ensures the highest level of security at sea.

MacGregor Manual (Bottom) Twistlocks

Manual twistlocks are operated entirely by hand, both for locking and releasing. They are typically used as bottom twistlocks in container sockets on deck and on hatch covers, where manual operation is easily accessible without the need for tools.

Known for their exceptional strength and reliability, manual twistlocks are the preferred choice for securing the most critical positions in container stacks, ensuring maximum safety in even the toughest conditions.

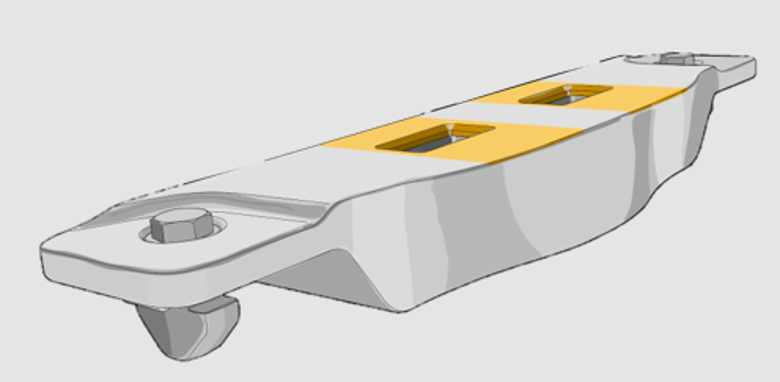

Midlocks

Midlocks are always used in conjunction with semi-automatic or manual twistlocks to ensure safely secured containers. Midlocks are used in 20ft container ISO gaps, but they can also be used in 20ft lashing gaps.

Midlock is efficient at reducing loading and discharging times because no locking or unlocking is required. This adds an additional safety feature for the operator.

Terminal Stackers

Terminal stacker is a flexible, easy to operate device that is used in cargo hold for keeping 20ft containers’ free-end non-moving in the 40ft cell guides. Easy to use hanging-type terminal stacker will increase the cargo efficiency of your container vessel.

External lashing

The MacGregor All Set design external lashing was introduced decades ago and has been a trusted design ever since.

Unlike internal lashings, the external lashing system secures the lifting side of the container instead of the compressed side, which reduces both forces. This allows the container stacks to be loaded with a better weight distribution, with heavier containers higher up in the stacks, compared to an internal lashing system.

Internal Lashings

The MacGregor internal lashing system has some unique features promoting cargo and working safety throughout its long working lifetime. The fail-safe turnbuckle locking system with slack-preventing function and the design of the swage-fitted rod head on the lashing bar make sure that the turnbuckles stay safely tightened under all conditions.

Vertical Lashings

Vertical lashings are designed to counteract lifting forces, such as those caused by wind loads, particularly in the outermost container stacks.

Each vertical lashing bar features a specially shaped head optimized for vertical positioning, ensuring secure and reliable performance. Usually the same turnbuckles used for cross lashings are also utilized with vertical lashings.

ISO-Gap Adapters

ISO Gap adapter is a boltable loose fitting or weldable fixed fitting, which is installed on existing container sockets with 20ft lashing gap in the middle of hatch covers. ISO Gap adapter enables mixed stow loading of containers after implementation. Mixed stow means the possibility to load 40ft containers on top of two 20ft containers.

Read more on the Cargo Boost page

Flat Racks and Storage Bins

MacGregor flat racks and storage bins are specially designed for the safe and efficient transport of twistlocks and terminal stackers on board ships.

Flat racks can be easily lifted and moved to various locations within the terminal to discharge the bins. This allows stevedores to quickly access the twistlocks, removing or attaching them to container corners before the containers are discharged or loaded onto the vessel.

Flat racks are available painted or hot dip galvanized.

LashMate Lashing Software

MacGregor in-house developed stowage calculation software, Lashmate, helps evaluate actual loading with respect to your vessel’s real stability conditions, taking into account the vessel’s installed lashings system and the forces to which they are exposed.